How to measure acme threads – Embark on a fascinating journey into the realm of acme threads measurement. This comprehensive guide will unravel the intricacies of this specialized field, empowering you with the knowledge and techniques to accurately assess the dimensions of these unique threads.

As we delve into the world of acme threads, we’ll explore the various methods for measuring them, providing a step-by-step guide to using a micrometer for precise measurements. We’ll also delve into the types of tools employed for this task, comparing their accuracy, cost, and ease of use.

Measuring Acme Threads

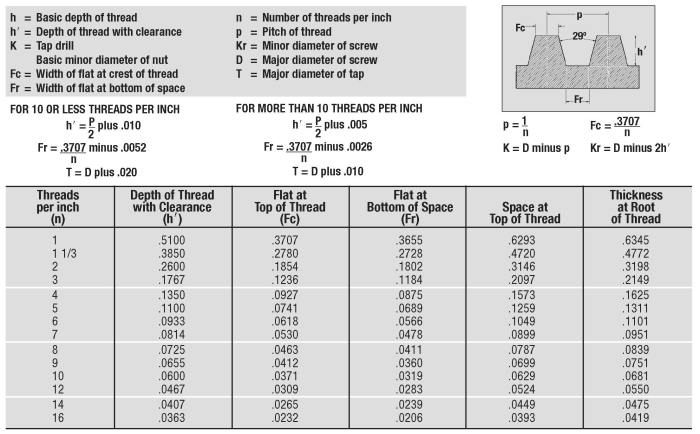

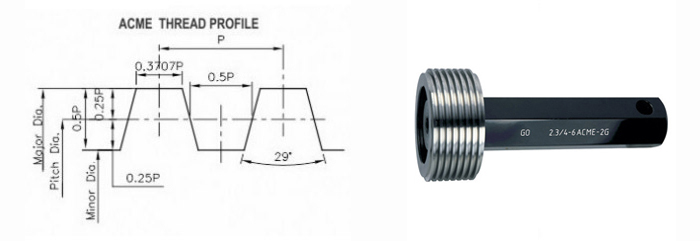

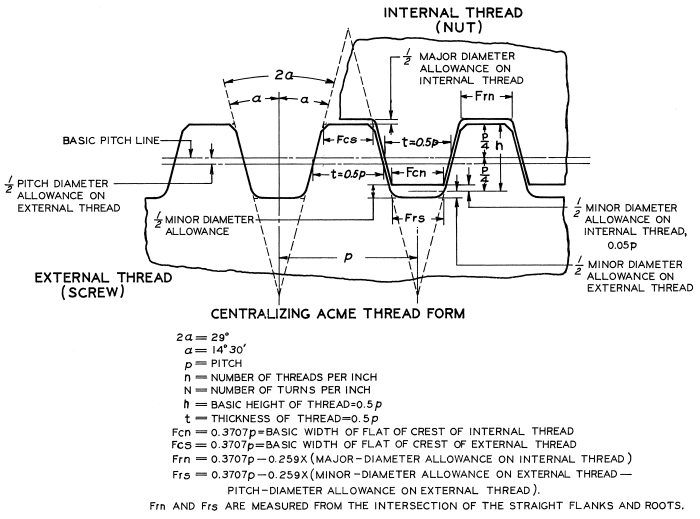

Acme threads are a type of trapezoidal thread used in various applications. Measuring these threads accurately is essential to ensure proper fit and function. Several methods can be employed to measure acme threads, each with its advantages and disadvantages.

To measure acme threads, you’ll need to use a special tool called an acme thread gauge. This gauge has a series of blades that are designed to fit into the threads of the acme screw. By using the gauge, you can determine the pitch of the threads, which is the distance between two adjacent threads.

This information can be used to identify the correct size of acme nut to use with the screw. Once you have the correct nut, you can assemble the acme screw and nut to create a strong and durable connection. If you’re looking for more information on acme threads, be sure to check out fry’s first 100 word list . This list includes the most common words used in the English language, and it can be a helpful resource for learning how to measure acme threads.

Measuring Acme Threads Using a Micrometer

A micrometer is a precise measuring instrument commonly used to measure acme threads. Here’s a step-by-step guide on how to measure acme threads using a micrometer:

- Clean the threads to remove any dirt or debris that could affect the measurement.

- Set the micrometer to zero using the adjustment knob.

- Place the threads between the anvil and the spindle of the micrometer.

- Gently tighten the spindle until it makes contact with the threads.

- Read the measurement on the micrometer scale. The measurement will be the pitch of the threads.

The pitch of acme threads is the distance between two consecutive threads, measured in inches or millimeters.

Comparison of Methods for Measuring Acme Threads, How to measure acme threads

| Method | Advantages | Disadvantages |

|---|---|---|

| Micrometer | Precise and accurate | Requires a skilled operator |

| Thread gauge | Easy to use | Less accurate than a micrometer |

| Optical comparator | Non-contact measurement | Expensive and requires specialized equipment |

Tools for Measuring Acme Threads

Measuring acme threads requires specialized tools to ensure accurate measurements. Several types of tools are commonly used, each with its advantages and disadvantages.

Types of Tools

- Micrometers:Micrometers are precision measuring instruments that use a calibrated screw to measure the distance between two points. They are commonly used to measure the pitch and diameter of acme threads.

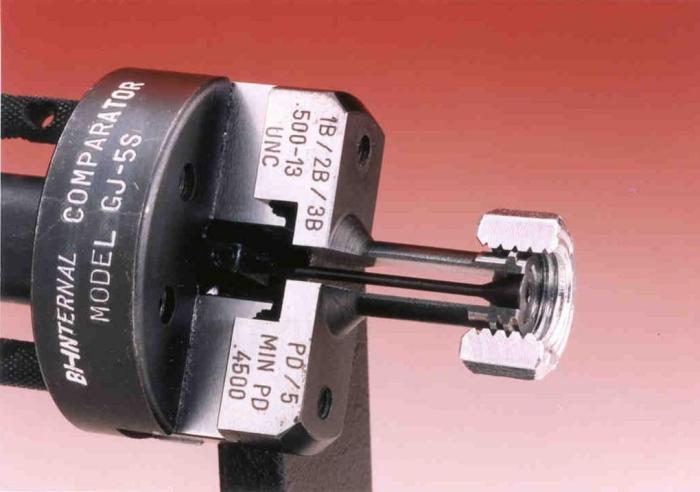

- Thread Gauges:Thread gauges are specialized tools designed to measure the pitch and form of threads. They consist of a set of blades with different thread forms and pitches, allowing for quick and easy identification of the thread type.

- Optical Comparators:Optical comparators use a projected image of the thread to measure its pitch and form. They provide a high level of accuracy and can also be used to inspect the thread for defects.

| Tool | Accuracy | Cost | Ease of Use |

|---|---|---|---|

| Micrometers | High | Moderate | Moderate |

| Thread Gauges | Moderate | Low | High |

| Optical Comparators | Very High | High | Moderate |

Calibration and Maintenance

Regular calibration and maintenance are crucial to ensure the accuracy of the tools used for measuring acme threads. Micrometers should be calibrated using standard gauge blocks, while thread gauges and optical comparators should be calibrated using traceable reference standards.

Proper maintenance includes cleaning the tools after each use, storing them in a dry environment, and protecting them from damage. By following these guidelines, the tools will provide reliable and accurate measurements for years to come.

Standards for Acme Threads

Acme threads are subject to various standards, ensuring uniformity and compatibility in their measurement and production. These standards are established by organizations such as the American National Standards Institute (ANSI), the International Organization for Standardization (ISO), and the Deutsches Institut für Normung (DIN).

ANSI Standards

- ANSI B1.5-1977: This standard specifies the dimensions, tolerances, and gaging practices for acme threads with a diameter range of 1/4 to 6 inches.

- ANSI B1.8-1978: This standard covers acme threads with a diameter range of 6 to 12 inches, providing specifications for their dimensions, tolerances, and gaging methods.

ISO Standards

- ISO 2901: This international standard defines the basic profile, dimensions, and tolerances for acme threads with a diameter range of 1 to 600 mm.

- ISO 2903: This standard specifies the gaging practices and tolerances for acme threads, ensuring consistent measurement and inspection.

DIN Standards

- DIN 103: This German standard covers acme threads with a diameter range of 8 to 60 mm, providing specifications for their dimensions, tolerances, and gaging practices.

- DIN 513: This standard defines the basic profile, dimensions, and tolerances for acme threads with a diameter range of 1 to 80 mm.

Adhering to these standards is crucial for accurate and consistent measurement of acme threads. They provide a common reference point for manufacturers, inspectors, and users, ensuring that threads meet the required specifications and perform as intended.

Applications of Acme Threads

Acme threads find widespread use in various industrial and commercial applications due to their unique characteristics and advantages. They are commonly employed in situations requiring high axial loads and precise positioning.

One notable application of acme threads is in lead screws, which convert rotary motion into linear motion. Lead screws are crucial components in machine tools, such as lathes and milling machines, where precise positioning and control are essential.

Advantages of Acme Threads

- High load-bearing capacity:The trapezoidal profile of acme threads provides a large contact area, enabling them to withstand significant axial loads.

- Self-locking:Acme threads exhibit self-locking properties, meaning they can resist axial movement under load without the need for additional locking mechanisms.

- Easy to manufacture:The relatively simple geometry of acme threads makes them easy to produce, contributing to their cost-effectiveness.

Disadvantages of Acme Threads

- Lower efficiency:Compared to other thread forms, acme threads have lower efficiency due to the sliding friction between the threads.

- Higher wear:The sliding friction can also lead to increased wear over time, requiring regular maintenance or replacement.

Factors to Consider When Selecting Acme Threads

When selecting acme threads for a particular application, several factors should be taken into account:

- Load capacity:The required axial load capacity should be carefully considered to ensure the threads can withstand the expected forces.

- Efficiency:The desired efficiency of the system should be evaluated to determine if acme threads meet the performance requirements.

- Durability:The expected wear and tear should be assessed to determine the suitability of acme threads for the application’s lifespan.

- Cost:The manufacturing and maintenance costs associated with acme threads should be factored into the decision.

Troubleshooting Measurement Errors

Accurate measurement of acme threads is crucial for ensuring proper fit and performance in various applications. However, several common sources of error can arise during the measurement process.

To avoid and troubleshoot measurement errors, it is essential to:

- Use properly calibrated measuring tools.

- Ensure the workpiece is clean and free of debris.

- Measure the threads at the correct location and orientation.

- Take multiple measurements and compare the results.

- Use the appropriate measuring technique for the specific type of acme thread.

Calibration and Maintenance of Measuring Tools

Regular calibration and maintenance of measuring tools are essential to ensure accurate measurements. Calibrated tools provide reliable and consistent readings, reducing the likelihood of errors. It is recommended to calibrate measuring tools according to the manufacturer’s specifications or industry standards.

Proper Cleaning of the Workpiece

Debris or contaminants on the workpiece can interfere with accurate measurement. Before measuring, ensure the workpiece is clean and free of any dirt, oil, or other substances that may affect the measurements.

Measurement Location and Orientation

Measuring acme threads at the correct location and orientation is crucial to obtain accurate results. The measurement should be taken at the designated measuring point, typically specified in the thread specifications or technical drawings. Additionally, the workpiece should be oriented correctly to align the threads with the measuring tool.

Multiple Measurements and Comparison

Taking multiple measurements and comparing the results can help identify and minimize errors. By repeating the measurement process several times, any outliers or inconsistencies can be detected. Comparing the results also allows for the calculation of an average measurement, which provides a more accurate representation of the thread dimensions.

Appropriate Measuring Technique

The appropriate measuring technique should be selected based on the specific type of acme thread being measured. For example, three-wire method, optical comparator, or coordinate measuring machine (CMM) may be used depending on the thread size, pitch, and application requirements.

FAQ Overview: How To Measure Acme Threads

What is the most accurate method for measuring acme threads?

Using a micrometer with a V-shaped anvil provides the highest level of accuracy for measuring acme threads.

How do I calibrate my micrometer for acme thread measurement?

Calibrate your micrometer using a certified acme thread standard or a gauge block with an acme thread profile.

What are the common sources of error when measuring acme threads?

Incorrectly setting the micrometer anvil, using a worn-out micrometer, or measuring the thread at an angle can lead to errors.